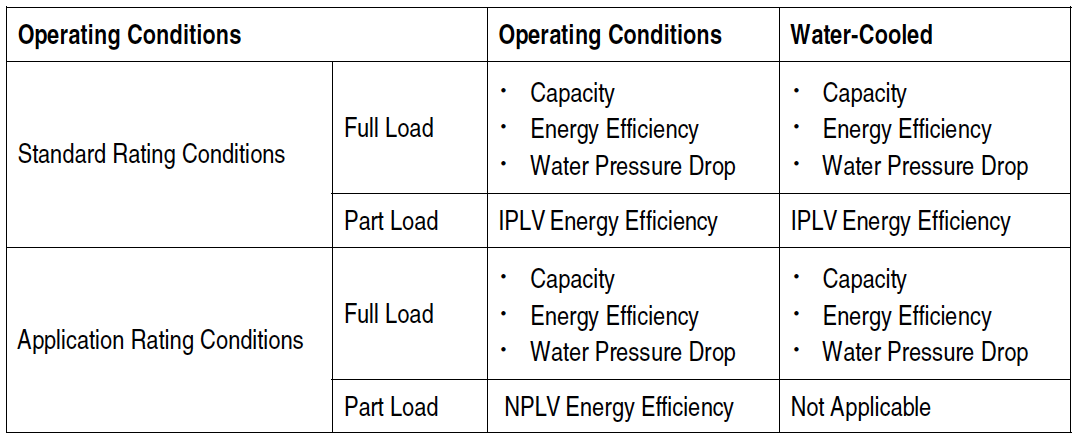

AHRI 550/590 Testing Standard

Included in Test Standard

50 Hz and 60 Hz Air-Cooled Chiller (ACCL) Product Inclusions

- Chillers between 0 and 600T manufactured after July 2013

- Units selected for use within the range of Application Rating Conditions as per AHRI Standard 550/590 (I-P)

- Hermetic or open type, electric motor driven

- Up to 600 volts

- All compressor types

- Units intended for use with glycol or other secondary coolant for freeze protection with a leaving chilled fluid temperature above 32.0°F are certified when tested with water at Standard Rating Conditions

60 Hz Water-Cooled Chiller (WCCL) Product Inclusions

- All compressor types

- Chillers rated between 0 and 3,000T

- Hermetic or open type electric motor driven

- Units selected for use within the range of Application Rating Conditions as per AHRI Standard 550/590 (I-P)

- Voltages up to 15,000 volts after June 15, 2011

- Positive Displacement Units intended for use with glycol or other secondary coolant for freeze protection with a leaving chiller

Overview

- Room Construction (Standard)

- Precision Conditioning Equipment (Standard)

- ± 1.0F Steady-State Air Side Conditions

- ± 0.5F Steady-State Water Side Conditions

- ± 1.0% Steady-State Water Side Flow

- Complete Controls, Instrumentation & Automation (Standard)

- Real time control, monitoring and data collection (Standard), Includes Process Variables, Pressure, Temperature, Mass Flow, Watts and Calculated Variables such as Capacity, Superheat, & Liquid Subcooling

- Remote monitoring and alarm functions (Standard)

- Unit Under Test Power Supply & Power Analyzers (Optional)

- RS-232, Ethernet and SQL server communications (Optional)

- Flexibility to add Analog or Digital data channels (Optional)

- 1 Year Warranty with on-call customer support (Standard)

- Operator Training (Standard)

- Preventative Maintenance & Service Programs (Optional)

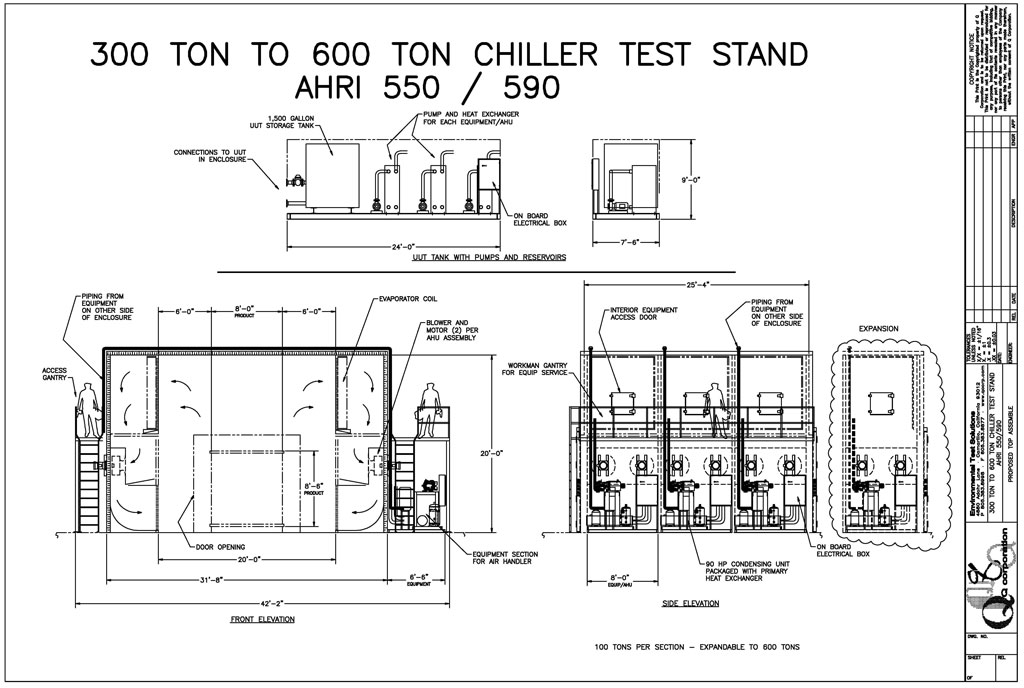

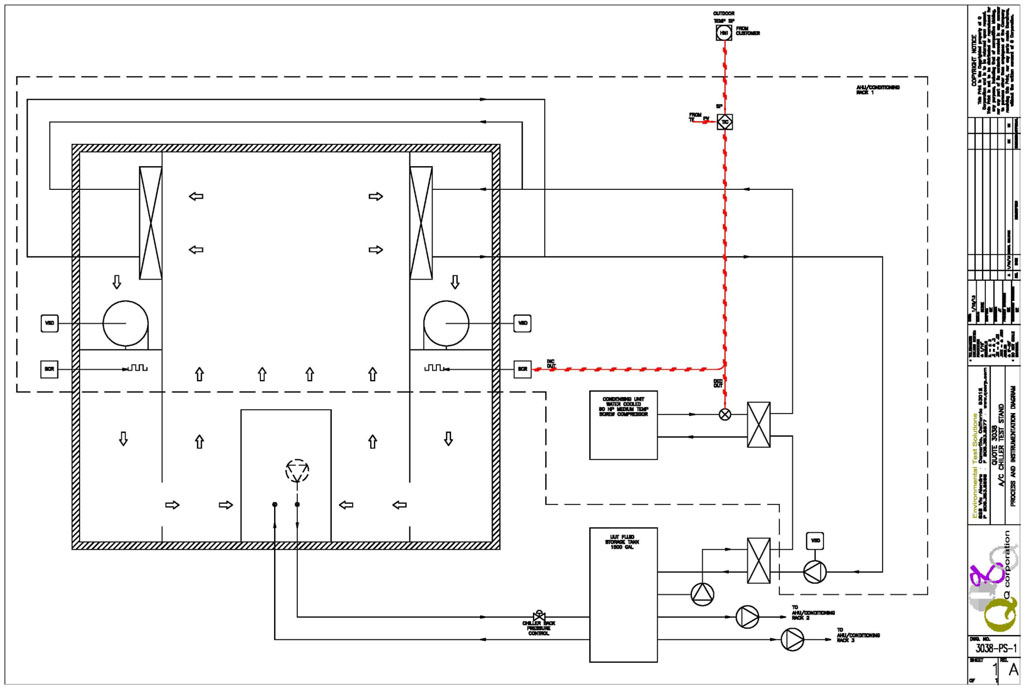

- Consist of numerous stand alone equipment packages integrated together at customer facility. 300T Base System (10:1 Turndown) includes three-3 100 ton air handling unit modules, each with integrated refrigeration and fluid supply modules that will utilize the unit under tests (UUT) cooling capability.

- The refrigeration system includes screw compressor packages that supply a flat plate heat exchange in the fluid loop for each AHU. This design allows for integration of supplemental AHU modules, capable of adding incremental 100T capacity. The design also enables each module to be built and shipped at Q’s manufacturing site with subassembly only required in the field. Each module is designed to appropriately fit on a truck transport for cross country delivery.

- Controls and data acquisition for the system will be achieved through an PLC with industry approved DAS rack. A computer performing LabVIEWTM software will be provided for operator interface. The system provided by Q will only provide transducers and hardware for system controls and core calculations.

- LabVIEWTM interface can be included in base package or as an option to standard touch screen interface

- Real time display of measured and calculated variables, including table and graph format.

LabVIEWTM software provides easy to use operator screen menus including:

- Airflow screen

- Pressure screen

- Thermocouple screen

- Calibration screen