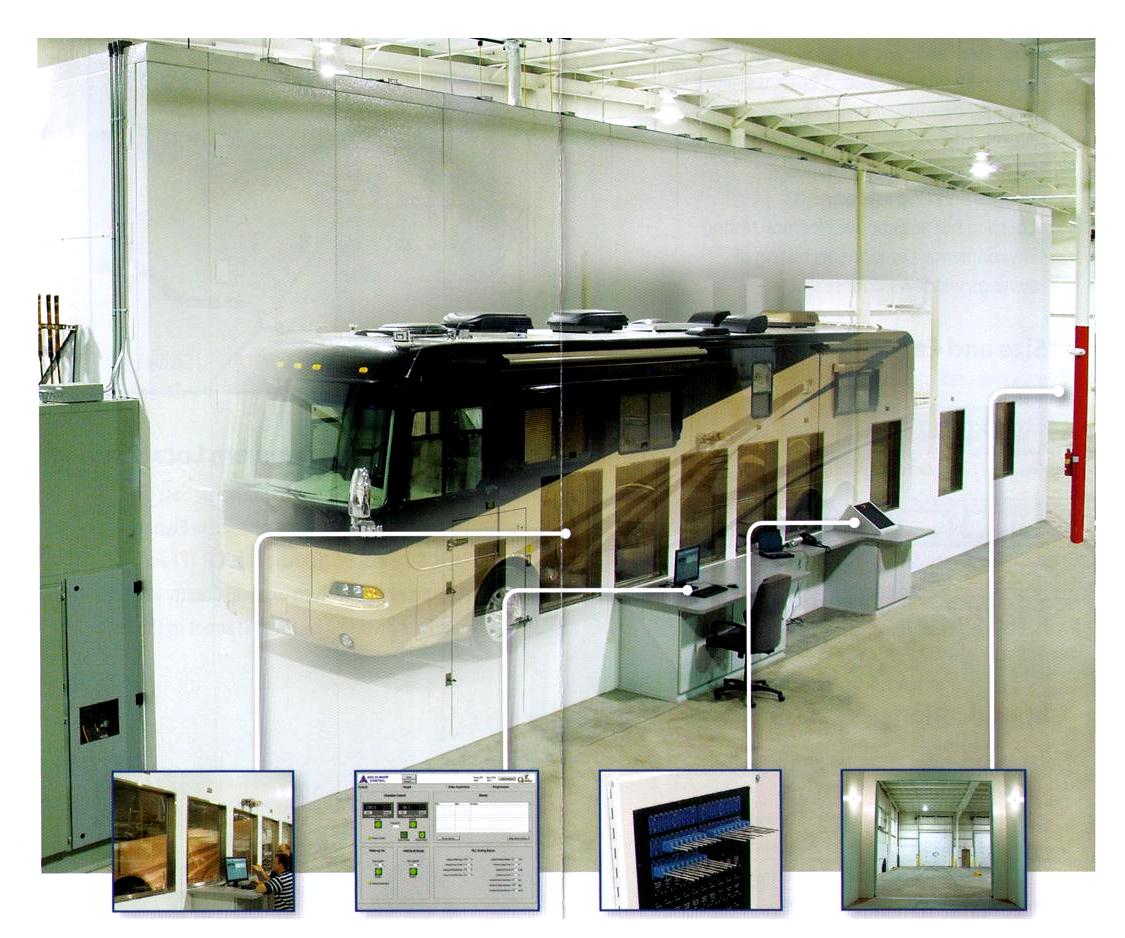

Class 8 Test Chamber

Features

- -40F dry air combustion system assures long term performance of chamber cooling coil.

- Optional solar array packages available with multiple zone control and vertical/side mounted profile.

- Direct expansion refrigeration system standard, options available for secondary “brine” conditioning for added control capabilities.

- Chamber can be integrated with external testing equipment including servo actuated road simulation.

- Optional sound attenuation packages availablefor hemi-anechoic testing.

- Integrated “Snow” generation and “Windshield” spray systems options available

- Data collection and computation through PLC based touch screen. Also available through LabVIEW® automation software packages.

Specs

Typical Internal Dimensions: 60’L x 17’W x 18’H

Typical Doors: 14’ x 14’ Vehicle Access / 3’ x 7’ Personnel Access

Access Ports / Windows: Several options available

Temperature Range: -40 to 160°+F

Temperature Sensor: RTD or Thermocouple

Humidity Range: 20 to 90% RH

Extended Range: 10 to 95% RH

Humidity Sensor: RH capacitive element

Airflow: 40,000 to 175,000 cfm frontal, side or ceiling mounted plenum

Exhaust: 600-1000 cfm standard

Dry Combustion Air Supply: 600 – 1,000 cfm standard

Control: Fully automatic, PLC driven

Control Interface: LabVIEW® software with PC interface