Automotive Compressor Calorimeter/Durability

Features

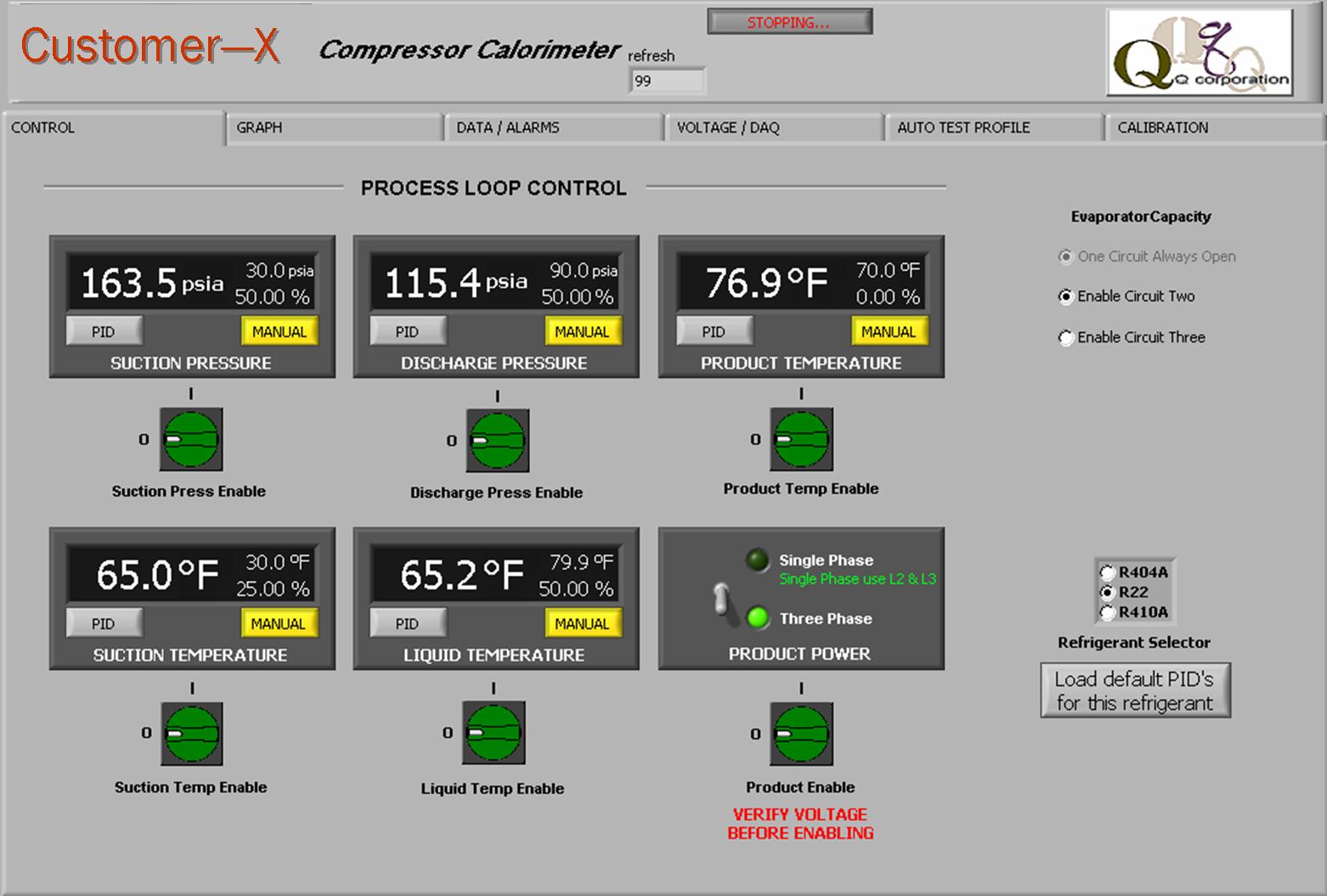

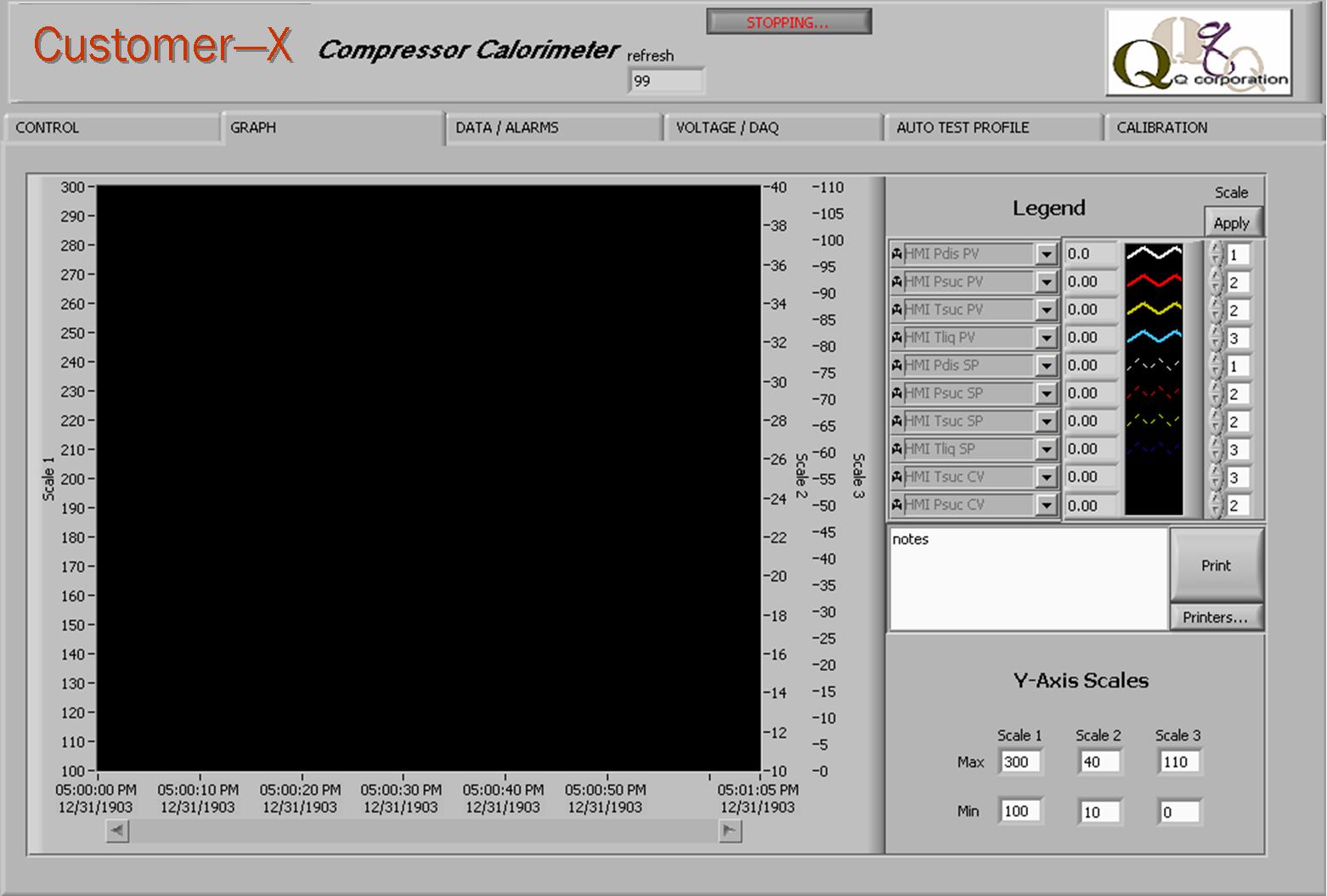

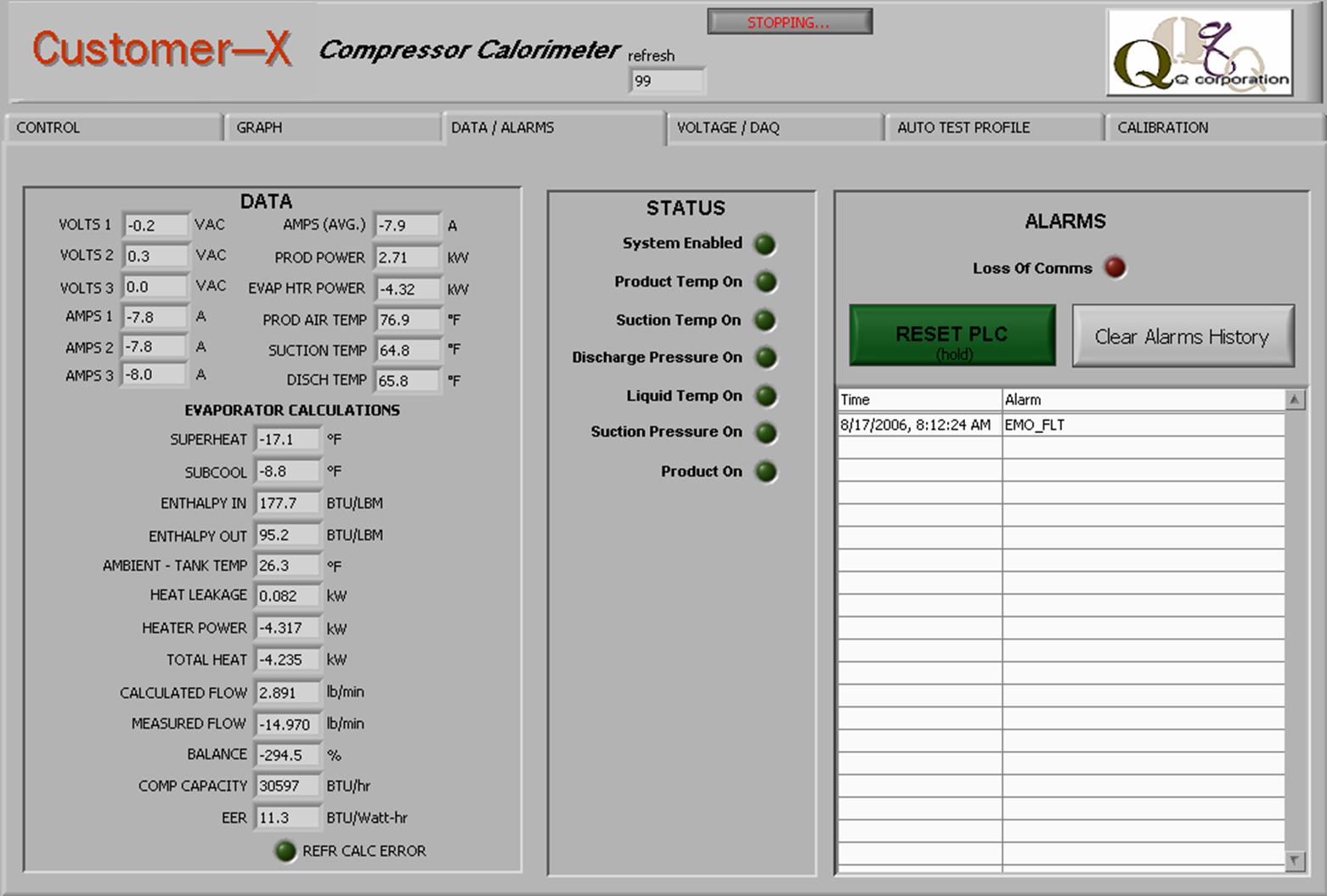

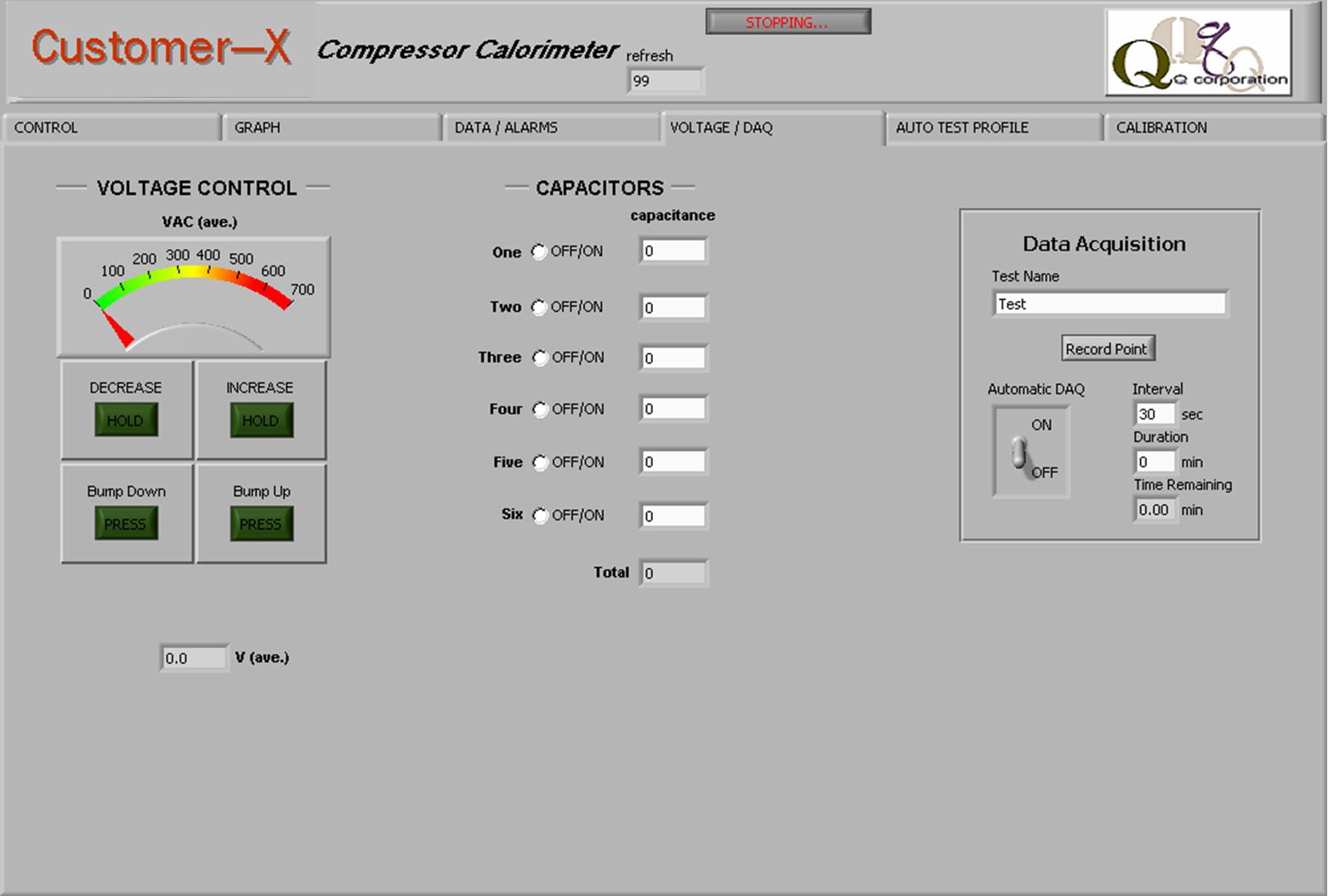

- Continual measurement and display of all data

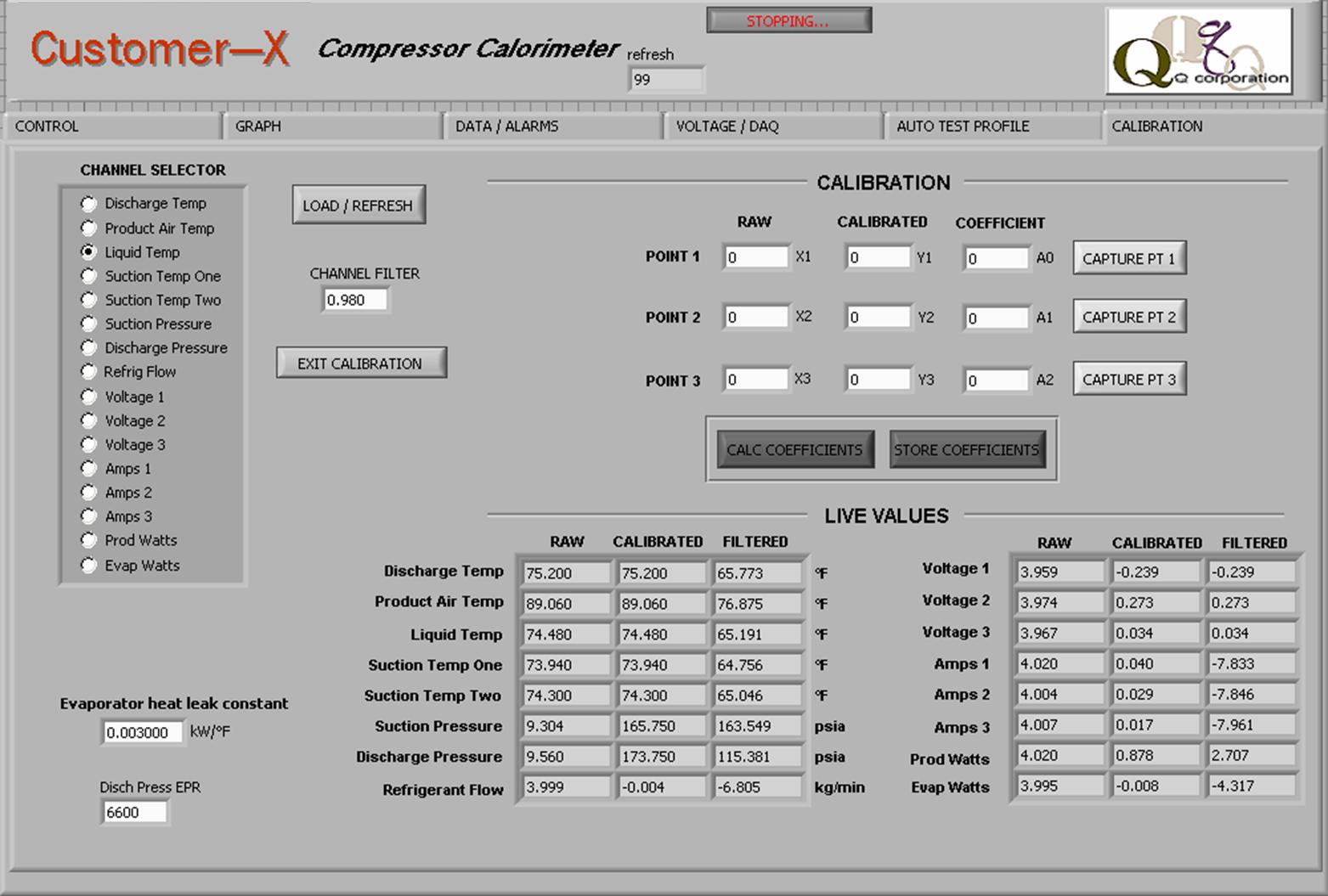

- NIST traceable calibration for all DAS sensors, multiple axis curve plotting of compressor performance

- Oil in circulation rate is controllable and repeatable

- Independent control of:

- Compressor discharge pressure

– Compressor suction pressure

– Compressor suction temperature

– Compressor rpm

– Compressor area air temperature - Unitized construction with enclosed equipment section and easy maintenance access

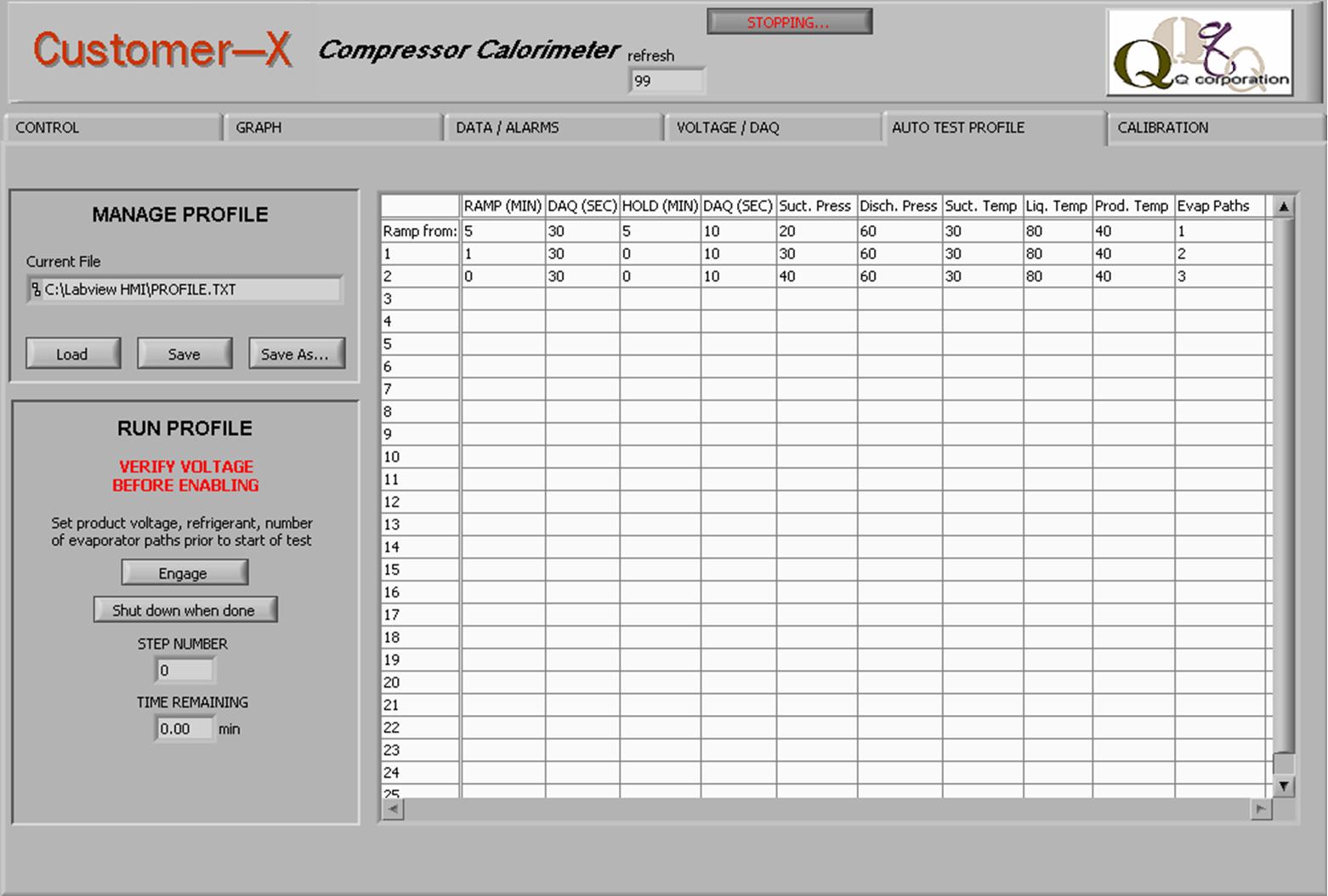

- Data collection and computation through PLC based touch screen, also available through LabVIEW® and Wonderware® automation software packages

Specs

Compressor Speed: 500 to 15,000 rpm

Refrigerant: R134a

Compressor Capacity: Up to 50,000 BTUH

Discharge Pressure: 70 to 120ºF (limited by 5 to 30ºF SC)

Suction Pressure Control: 0 to 80 psig

Suction Temperature: Variable by customer supplied TXV

Discharge Pressure: 150 to 450 psig

Compressor Chamber Temp: -40 to 350 F

Evaporator Airflow: 60 to 600 cfm

Temperature: 70 to 300 F

Refrigerant Flow Measurement: Coriolis

Airflow Measuremen:t V-Cone

Temperature Measurement: RTD

Control: Fully automatic, PLC driven

Control Interface: LabVIEW® software with PC interface