Refrigerator, Freezer & Display Case Test Systems

Household Refrigerators, Refrigerator-Freezers, Freezers, & Household Wine Chillers

- Performance Testing

- No-load pull-down

- Simulated load test

- Ice making test

- Temperature rise test

Durability Testing

- External Surface Condensation

- Internal Moisture Accumulation

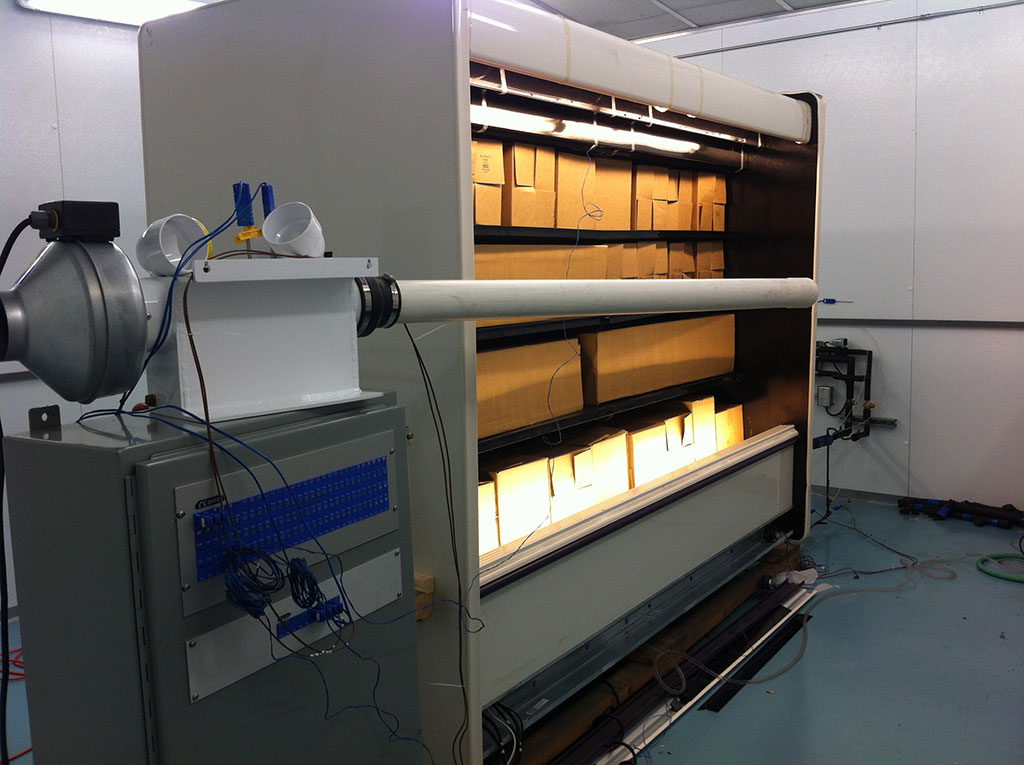

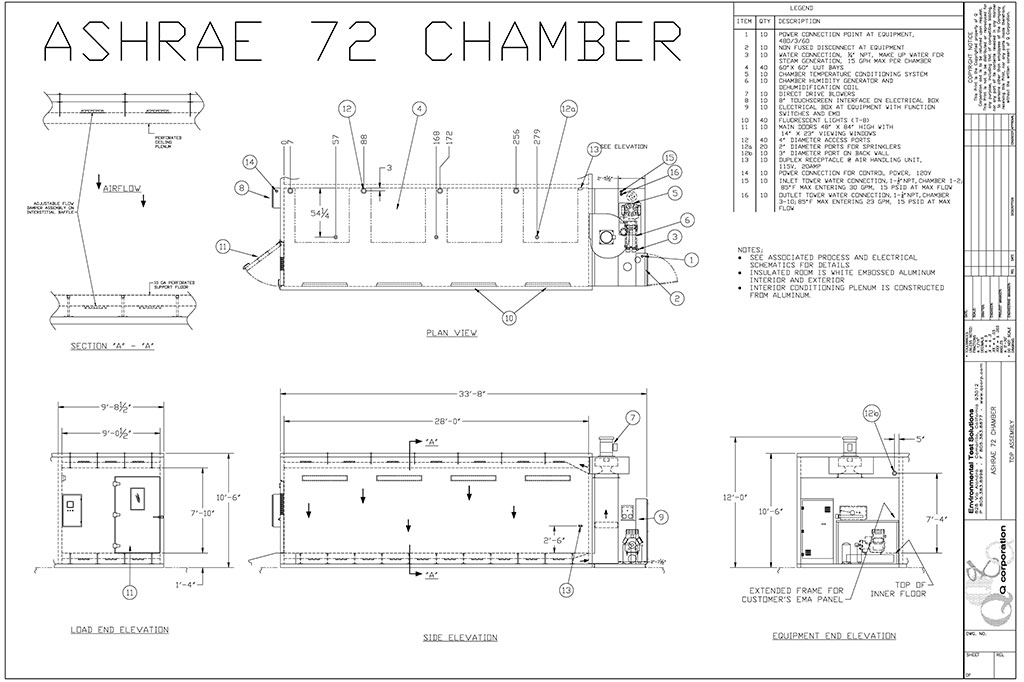

Overview

- Ambient Room with Drop Ceiling / Raised Floor Construction (Standard)

- Precision Room Conditioning Equipment (Standard)

- Not to exceed (NTE) 0.5 F/ vertical foot gradient, Steady-State Conditions

- Airflow NTE 50 FPM

- Complete Test Room Controls (Included)

- Automated real time control, monitoring and data collection (Optional), Process Variables, Pressure, Temperature, Mass Flow, Volts, Amps, Watts, kWh, Hz

- Remote monitoring and alarm functions (Standard)

- Unit Under Test Power Supply & Power Analyzers (Optional)

- RS-232, Ethernet and SQL server communications (Optional)

- Flexibility to add Analog or Digital data channels (Optional)

- 1 Year Warranty with on-call customer support (Standard)

- Operator Training (Standard)

- Preventative maintenance & Service Programs (Optional)

Room Airflow Design

- Airflow operation can be floor to ceiling or ceiling to floor depending on customer test unit requirements.

Supply

- Supply plenum consist of a set of ducts that distributes the airflow in a uniform effect over the entire workspace.

- The primary plenum (or interstitial plenum) is constructed from 16 ga aluminum sheet with adjustable sliding dampers. These dampers (each damper can be adjusted independently) will allow the air to be spread evenly over the entire workspace.

- The secondary plenum is constructed from .” polypropylene and is perforated to allow the optimized airflow to settle around the product evenly. All dampers are tool to adjust with out removing ceiling panels.

Return

- The return plenum (ex. floor) is constructed in the same manner as the supply plenum.

- The floor that the product sits on is constructed from 10 ga stainless steel. This steel is perforated to match the supply plenum and falls within the range of the airflow requirement.

- After the air passes through the perforated floor it is directed through any one of the many adjustable sliding dampers that are used for flow control at this stage in the process.

- All floor dampers are accessible to adjust the airflow as required with out removing panels, they are mounted in a 16 ga interstitial plenum that separates the perforated floor from the inlet to the conditioning plenum.

- 8” touch screen interface mounted on electrical box.

- Touch-panel allows programmable profile control of duration, cycles, and looping of up to 10 steps.

- Allen Bradley Micrologix 1500 PLC control device

- 120V A/C Digital In/Out

- Audible and visual annunciation Alarm Outputs

- Optional LabVIEWTM Software w/ added DAQ hardware can be provided.