Water Sourced Heat Pumps

Part 1, Water to Air heat pumps

- Confirm ISO 13256 Standard , Max & Min Operating Heating & Cooling Capacity,[W]

- Net Heating, Net Cooling Capacity (W)

- Energy Efficiency Ratio EER, Coefficient of Performance, COP, (W)

Part 2, Water to Water/Brine heat pumps

- Confirm ISO 13256 Standard , Max & Min Operating Heating & Cooling Capacity, [W]

- Net Heating, Net Cooling Capacity (W)

- Energy Efficiency Ratio EER, Coefficient of Performance, COP, (W)

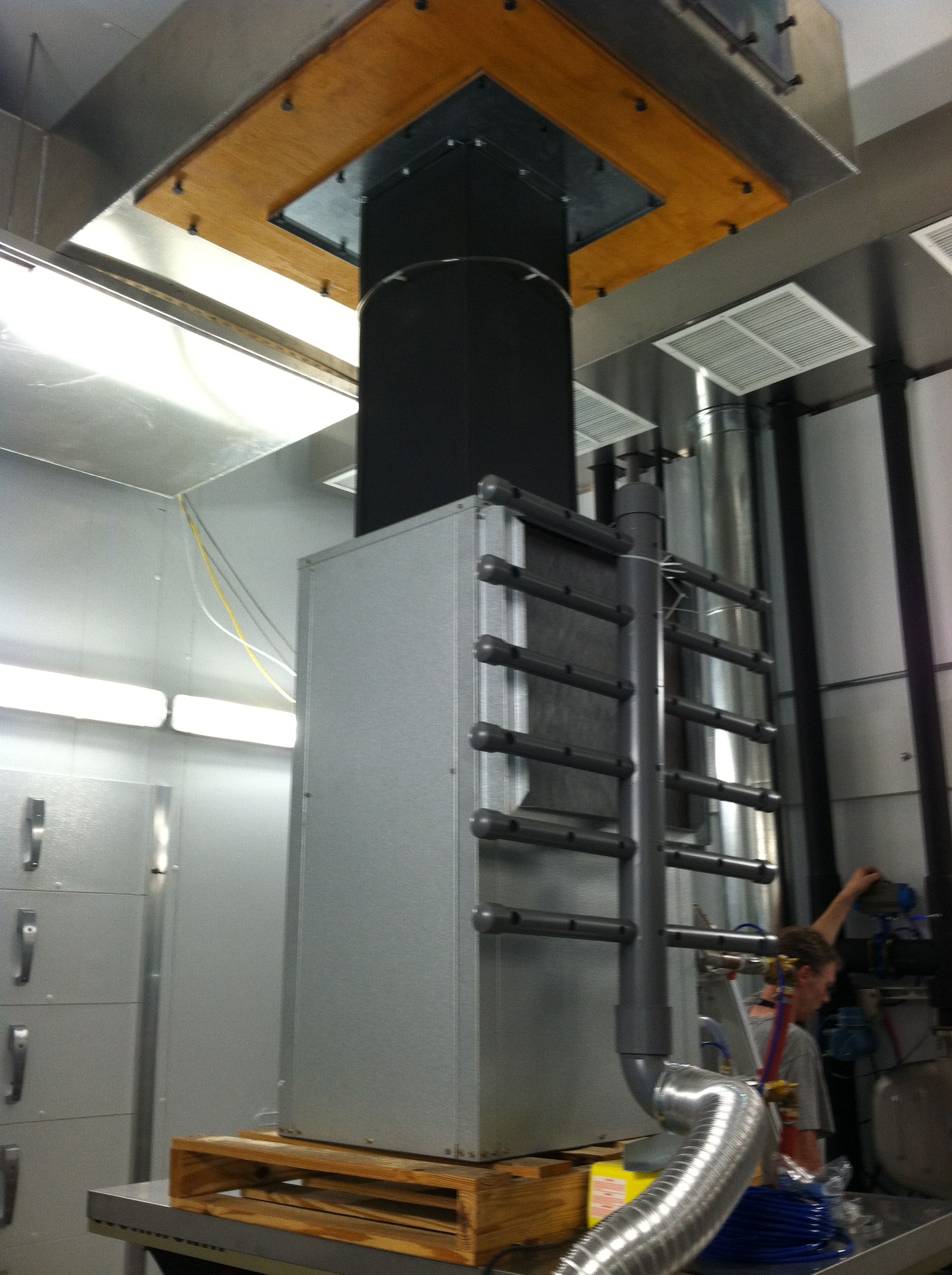

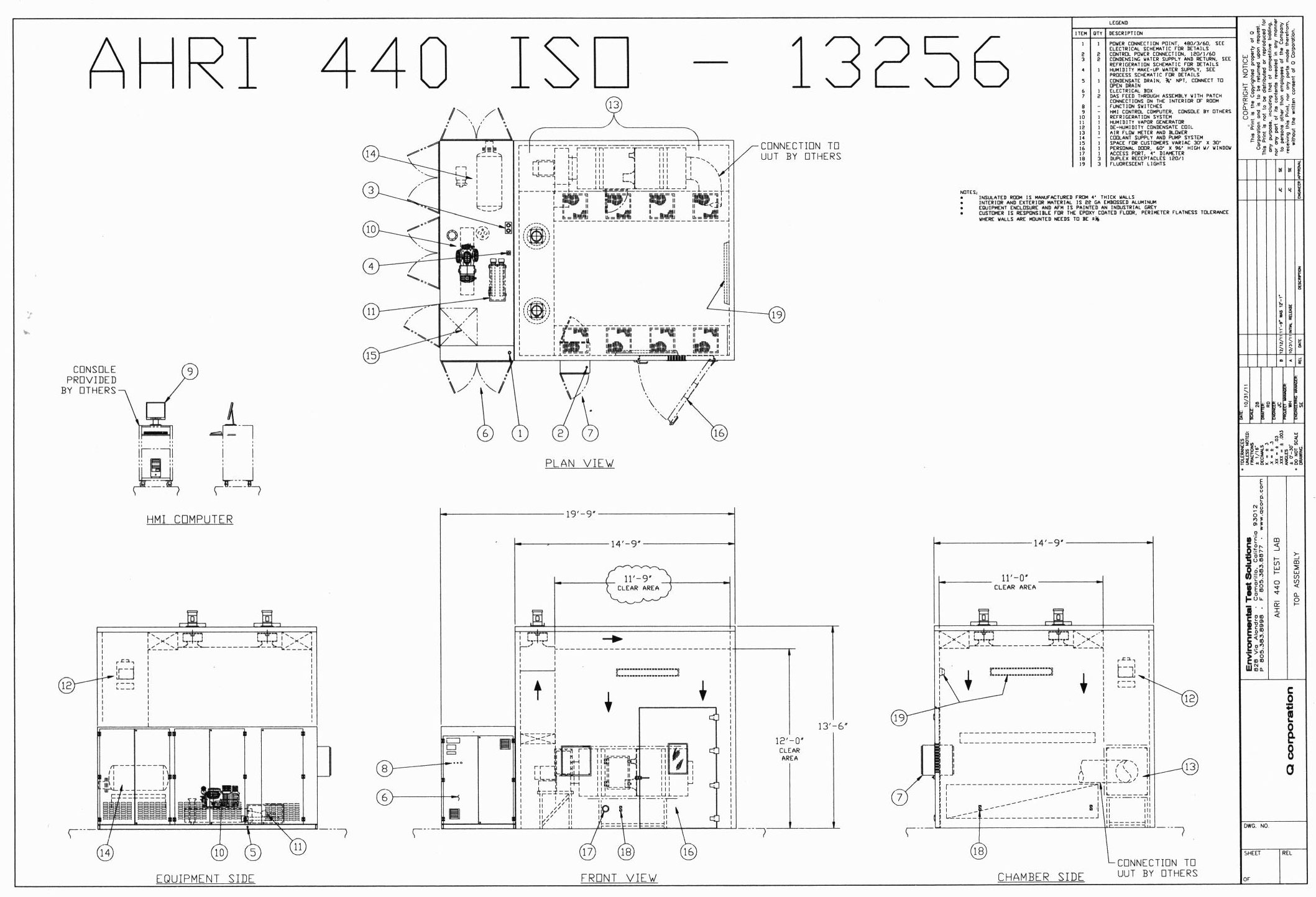

Overview

- Indoor Room Construction (Standard)

- Precision Room Conditioning Equipment (Standard)

- ± 0.2 F / ± 0.5 F dP Steady-State Conditions

- Part 1 Fluid Supply Module (Standard), part 2 (Optional)

- Complete Controls, Instrumentation & Automation (Standard)

- Real time control, monitoring and data collection (Standard), Includes Process Variables, Pressure, Temperature, Mass Flow, Watts and Calculated Variables such as Capacity, Superheat, & Liquid Subcooling

- Remote monitoring and alarm functions (Standard)

- Unit Under Test Power Supply & Power Analyzers (Optional)

- RS-232, Ethernet and SQL server communications (Optional)

- Flexibility to add Analog or Digital data channels (Optional)

- 1 Year Warranty with on-call customer support (Standard)

- Operator Training (Standard)

- Preventative maintenance & Service Programs (Optional)

Fluid / Brine Supply System

- Chilled and hot water conditioning systems to simulate Ashrae / ARI 13256.1 & 13256.2 test conditions

- Integral for all water sourced heat pump testing & calorimetry

- Heat exchanger pressure drop and performance

- Variable speed supply pump, enabling set-point control of fluid flow through test piece or process

- Sensors can be added as needed to provide optimum value of data points

- Used as a stand alone system or integrated with other Q Corporation supporting modules, including airflow supply systems

- LabVIEWTM interface can be included in base package or as an option to standard touch screen interface

- Real time display of measured and calculated variables, including table and graph format.

LabVIEWTM software provides easy to use operator screen menus including:

- Airflow screen

- Pressure screen

- Thermocouple screen

- Calibration screen

- Automatic Test Profile screen

- Password Protection

- Power screen\Capacity screen