Compressor

Calorimeter

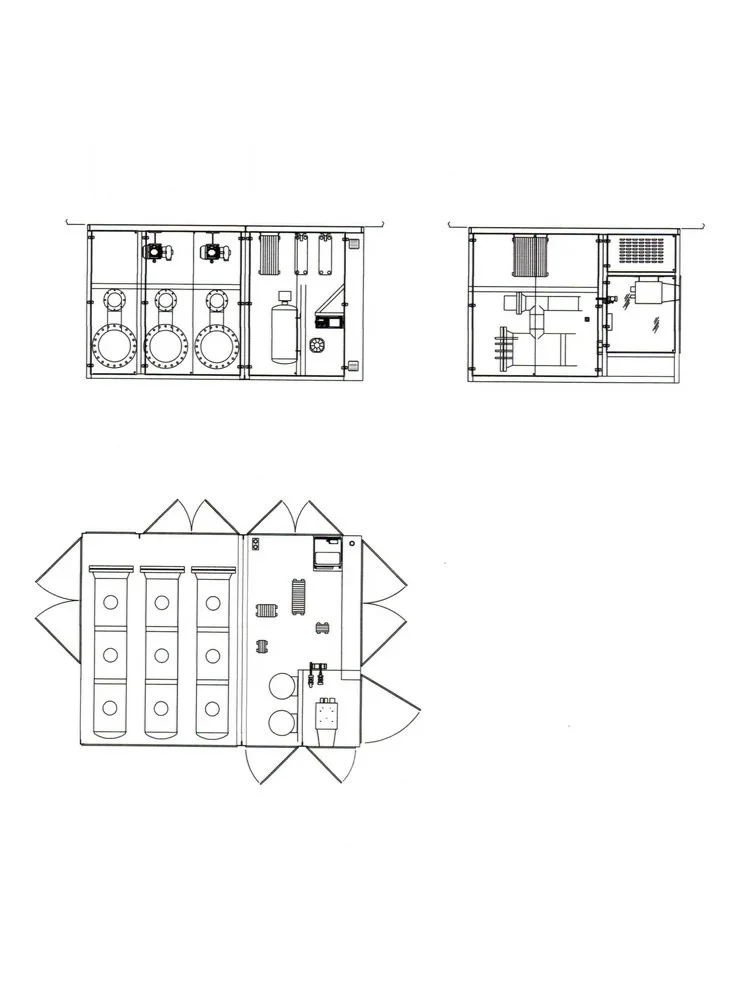

Overview

Designated for the commercial and vehicle HVAC compressor testing industry. Two available performance options including durability or calorimetry. Critical data collection includes accurate measurement of capacity, power input, as well as various measured and calculated performance values. System can be designed to perform within the prescribed operating ranges of R-134A, R-1234yf, R-404A, R-410A, R-744A and R-22. Other refrigerant designations can also be considered.

Features

Secondary brine loop for isolation and control of discharge pressure

NIST traceable calibration for all DAS sensors, multiple axis curve plotting of compressor performance

User configurable durability testing profiles

Oil in circulation rate is controllable and repeatable

Compressor discharge pressure

Compressor suction pressure

Compressor suction temperature

Compressor motor supply voltage

TXV inlet sub-cooling

Evaporator power input

Compressor area air temperature

Secondary refrigerant evaporator with ASME pressure rated vessel

Unitized construction with enclosed equipment section and easy maintenance access

Technical Specifications

-

Capacity: 1 to 170 Ton

Discharge Pressure Range: Variable based on application

Suction Pressure Range: Variable based on application

Suction Temperature Range: Variable Based on application

Refrigerant Flow: Coriolis

Temperature: RTD

Evaporator Loading: 5 kW to 600 kW -

Single Phase Voltage: 100 to 275 VAC

Single Phase Current: 20 to 150 A – Typical

Three Phase Voltage: 160 to 660 VAC – Typical

Three Phase Current: 15 to 210 A – Typical

Primary Frequency: Line Frequency (50 or 60 Hz)

Secondary Frequency: 50 or 60 Hz -

Compressor Speed: 500 to 15,000 rpm

Compressor Power: 10 to 100 hp -

Fully automatic PLC-based control algorithms

Real time display of measured and calculated variables,

Multi format, multi axis, multi pen graphing capabilities

Complete control interface to equipment

Calibration support for internal or external traceable calibration

Multi test automated sequencing

Password Protection

Real time calculation of all required values

Data storage for export to external data analysis

Ethernet, MODBUS and SQL server communications