Thermal Cycle Testing

Overview

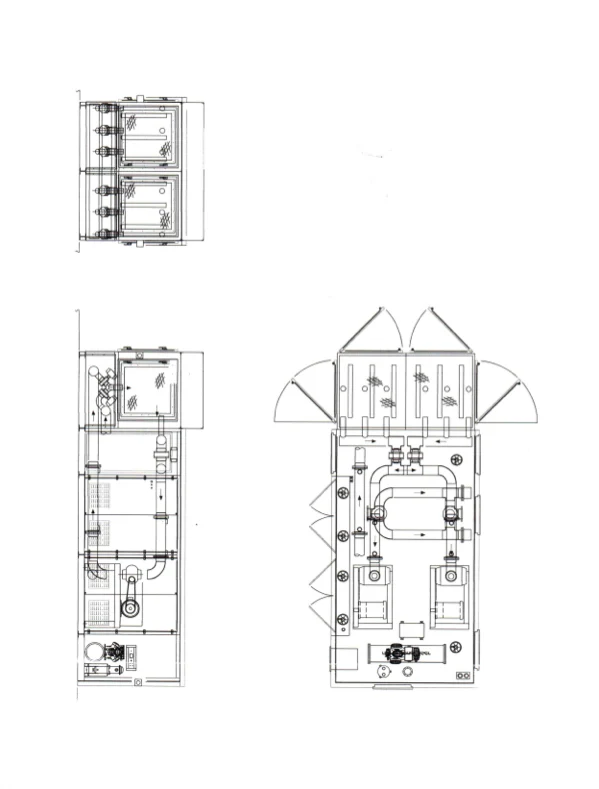

Today’s tough testing standards demand performance and reliability regardless of the weather conditions. Standard cold start procedures are now being succeeded with more extreme temperature cycling requirements. Repetitive and extreme temperature cycling conditions that engine and heat exchanger systems will experience throughout their life cycle has become the standard. Q Corporation manufactures glycol, water and oil supply systems capable of providing accurate flow capacities with precision temperature control. Although Q Corporation has several standard packaged offerings, we specialize in custom designed systems, including “refrigerant to coolant” and “brine to coolant” systems.

Use-Case Examples

Product failure testing of Condenser, Radiators, Oil Coolers, Heat Exchangers, Powertrain & Hydraulic Components. Perform to U/L, SAE, JIS and other industrial pressure testing specifications.

Verify long term durability and the effects of extreme thermal cycling on Charge Air Cooler heat exchangers. Simplicity of design and function assures long term performance and dependable results. Automotive to Class 8 CACs.

Thermal shock cooling systems for dynamic cooling applications involving engine cold start testing, heat exchanger thermal cycling including engine, heater core and radiator and critical process cooling.

Features

Pressurized feed control options

Thermal cycling systems available with hot & cold reservoir

Remote set point capability

Portable systems available

Automatic leak detection

Precise and real time data acquisition of all specified parameters

Also available as a “boost chiller” for additional cooling capacity to an existing cooling system

Operation provides for energy efficient staging of compressor systems, high tolerance to varying loads across conditioning coils

Technical Specifications

-

Temperature: -30F to 250F

Cycle Time: Up to 1 Hz

Volume Displacement: Variable

Media: Water, Glycol, Oil

Flow: Up to 100 gpm+ per UUT

Flow Meter: Coriolis or fixed orifice -

Transition: 10 gpm to 150 gpm+

Turndown: 10:1 turndown on control

Temperature Range: -70 to 350°F

Temperature Sensor: RTD or thermocouple -

Testing Capacity: 2 parts at a time (standard offering)

Cycle Rate: 30 cycles per hour, typical

Hot Temperature Range: 350° to 700°F+

Cool Temperature Range: Water supply temperature + 12°F to 130°F

Temperature Stability: +/- 10°F

Charge Air Airflow: 10 to 150 lb./min per Unit

Charge Air Supply: Rotary Vane Blower, Variable Speed Drive

Maximum Pressure Drop 6 psi -

Temperature Range: -40F to 250F

Conditioned Flow Range: 5 gpm to 150 gpm+

Operation: Stand alone, w/ process water cooling or “boost chill”

Capacity: 60 HP to 600 HP -

Fully automatic PLC-based control algorithms

Real time display of measured and calculated variables,

Multi format, multi axis, multi pen graphing capabilities

Complete control interface to equipment

Calibration support for internal or external traceable calibration

Multi test automated sequencing

Password Protection

Real time calculation of all required values

Data storage for export to external data analysis

Ethernet, MODBUS and SQL server communications