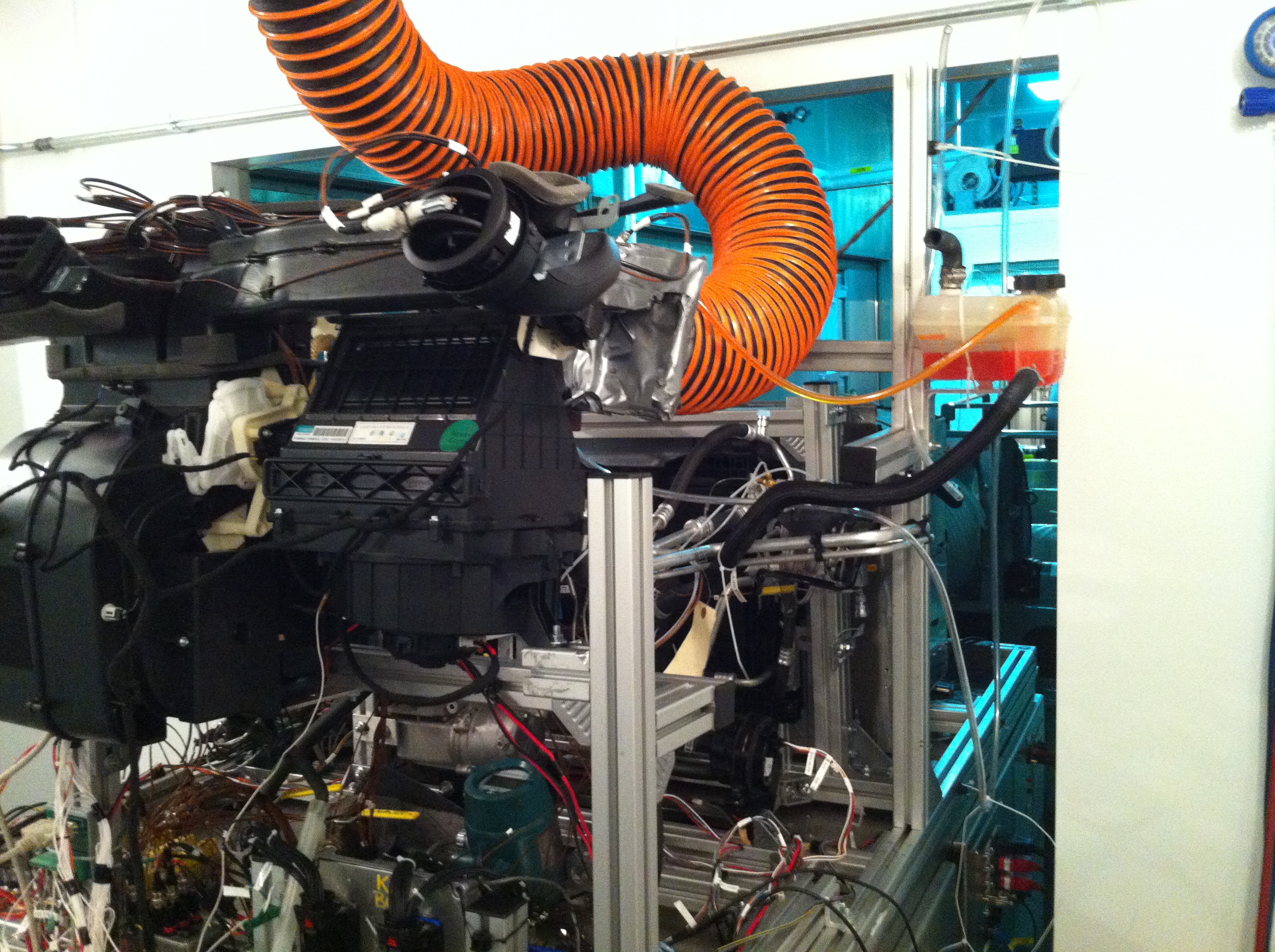

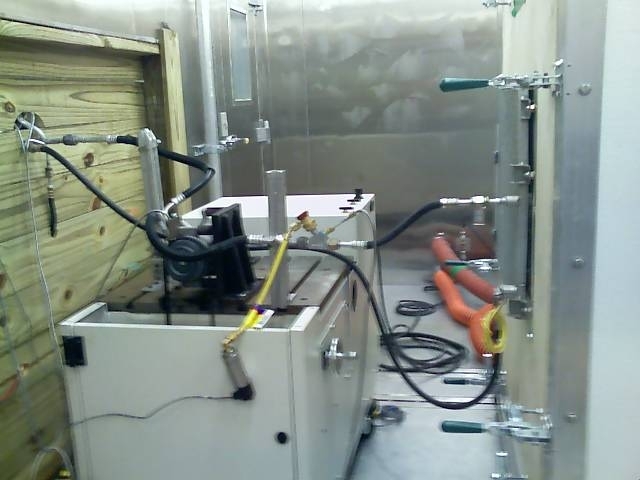

Automotive AC System Test Room

Features

- Ability to simulation any “real world” testing condition w/o leaving the lab environment

- Typical system has a minimum 18 control loops

- Ability to clutch cycle, ramp rpm and measure applied torque (optional) to AC compressor.

- Ability to provide heat pump testing capability and HEV cooling simulation.

- All supporting modules packaged and efficiently integrated within adjacent mechanical room, minimizing floor space requirement. Design allows for easy access for service and preventative maintenance

- Options available for glycol conditioning system for performing heater core testing

- Real time data collection and computation through PLC based touch screen, also available through LabVIEW® automation software packages

Specs

Main Cabin Conditioned Room Air

Temperature: -40C to 80C

Humidity: 20% to 90% RH

Conditioned Air to Primary HEB / EHAD

Temperature: -40C to 80C

Humidity: 20% to 90% RH

Airflow: 50 to 600 cfm

Conditioned Air to Secondary HEB / EHAD

Temperature: -40C to 80C

Humidity: 20% to 90% RH

Airflow: 50 to 600 cfm

Underhood Conditioned Room air

Temperature: -40C to 80C

Humidity: 20% to 90% RH

Conditioned Air to Condenser

Temperature: -40C to 80C

Humidity: 20% to 90% RH

Airflow: 500 to 12,000 cfm

Conditioned Air to Compressor

Temperature: -40C to 110C

Power Supplies (12V / 42V)

HEB Blower

Condenser Fan

Compressor Clutch

Control

Fully automatic, PLC driven

Control Interface

LabVIEW® Automation Software