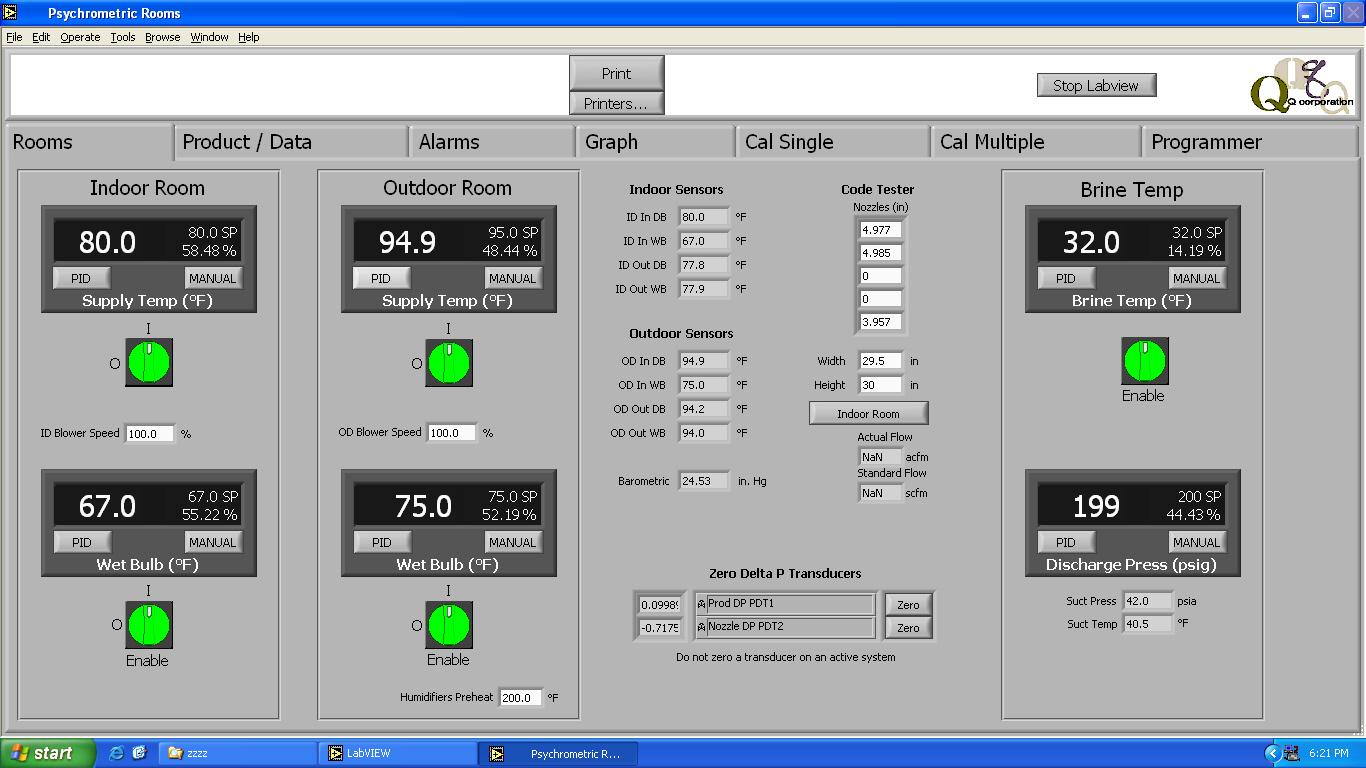

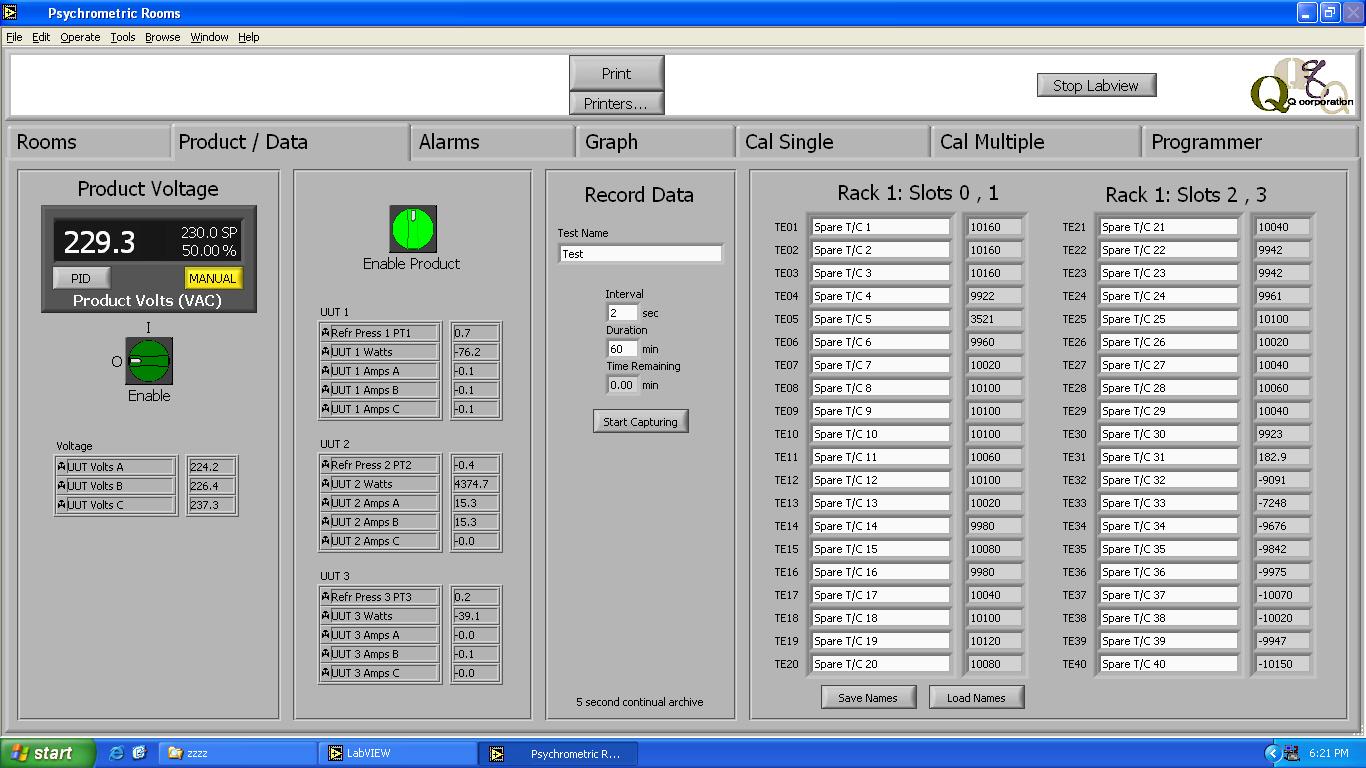

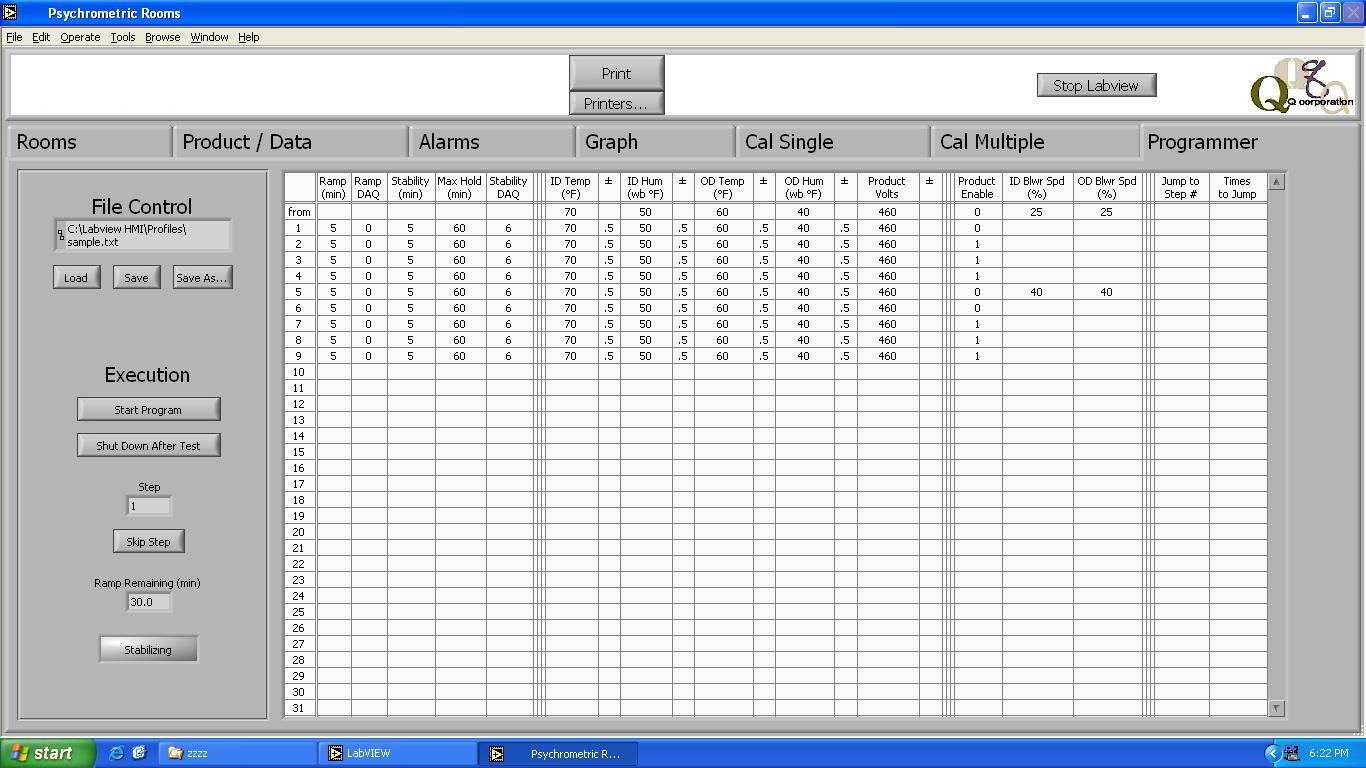

Automation Software and Controls Integration

Control of all the test stands function for unattended testing

Features:

- Graphical display of all hardware channels

- Automated control of preset points

- Real time display of calculated variables

- Alarm Annunciation

- Tabular Display

- Test Profiles

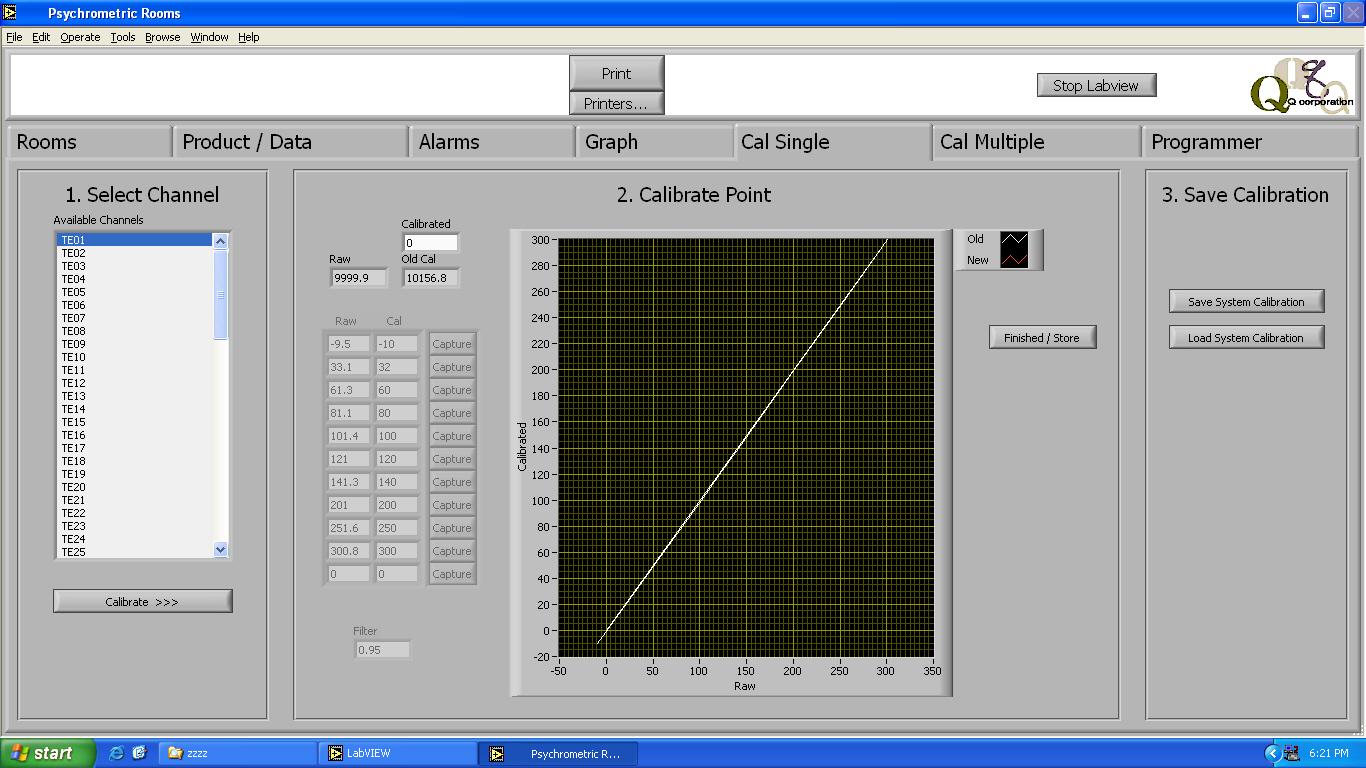

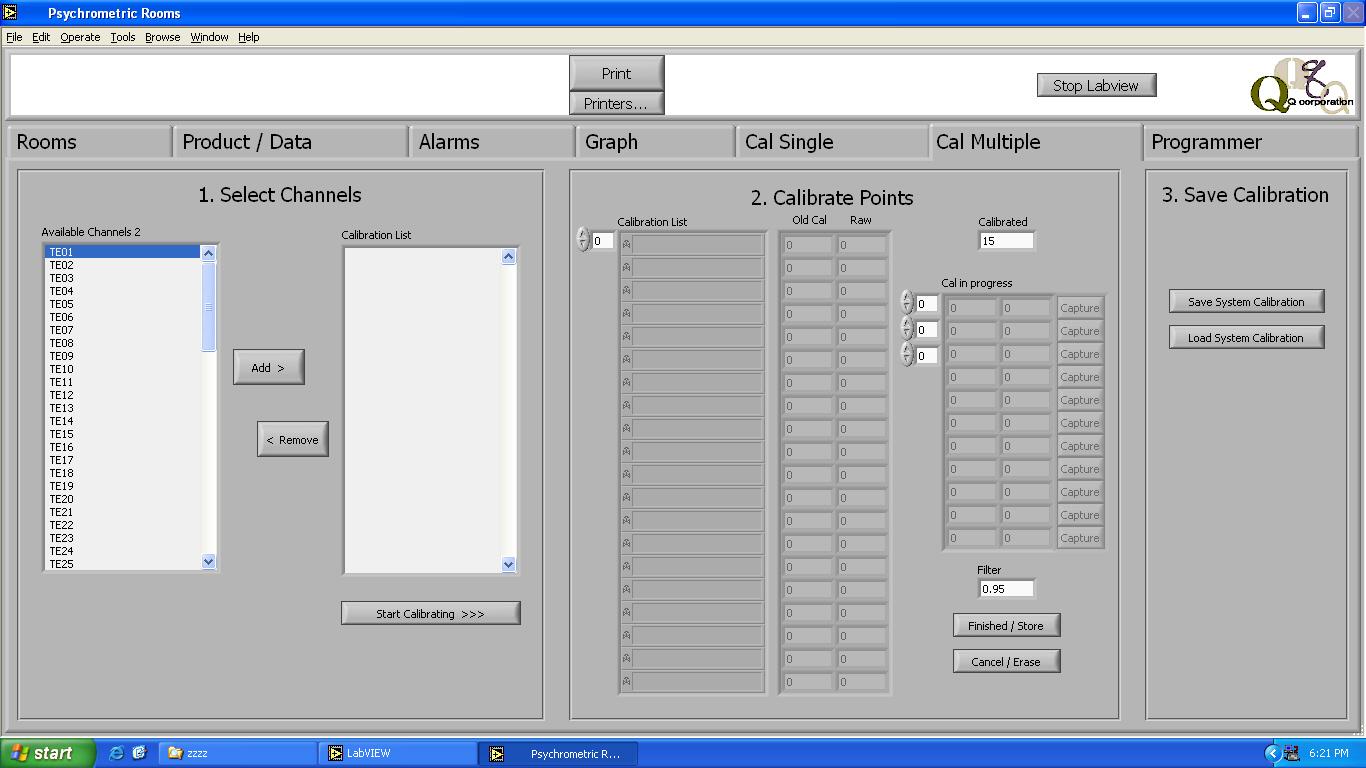

- Calibration procedures built in

- Web based display and control

- Event based data acquisition

- Data reporting to database or Excel (Windows™ Suite software)

- Ability to pre-program step functions to next set point to based on system stability

- Process Display

Preferred Software Platforms: LabVIEW™

Data Acquisition

- Including temperature, pressure, current, velocity, strain, displacement, and other physical phenomena.

- Data acquisition through the a PC card based unit, rack system, or PLC

- Hardware platforms: Yokogawa, National Instruments, Fluke, Agilent

- Measurement transducers: RTD’s, Thermocouples, Pressure, Differential pressure, RPM, Voltage, Current, Wattage, Power Factor, Stain Gage, Turbine flow, Coriolis flow meter, Humidity, thermal imaging camera’s, infrared temperature, torque, oil in circulation, and Airflow measurement— ASHRAE nozzles, V-cone, Brandt nozzle, anemomete

Controls

- Control architecture based on Individual PID controllers, Programmable Logic Controllers (PLC), and software based

- Choose from numerous modules to control digital, analog, specialty and distributed I/O signals

- Operator Interface options include: Computer, Touch Screen Display, or Ethernet

- Hardware platforms: Allen-Bradley, National Instruments, Watlow, Omron, Siemens, Modicon, Automation Direct, Yokogawa, Honeywell, etc