Charge Air Cooler Thermal Cycle

Features

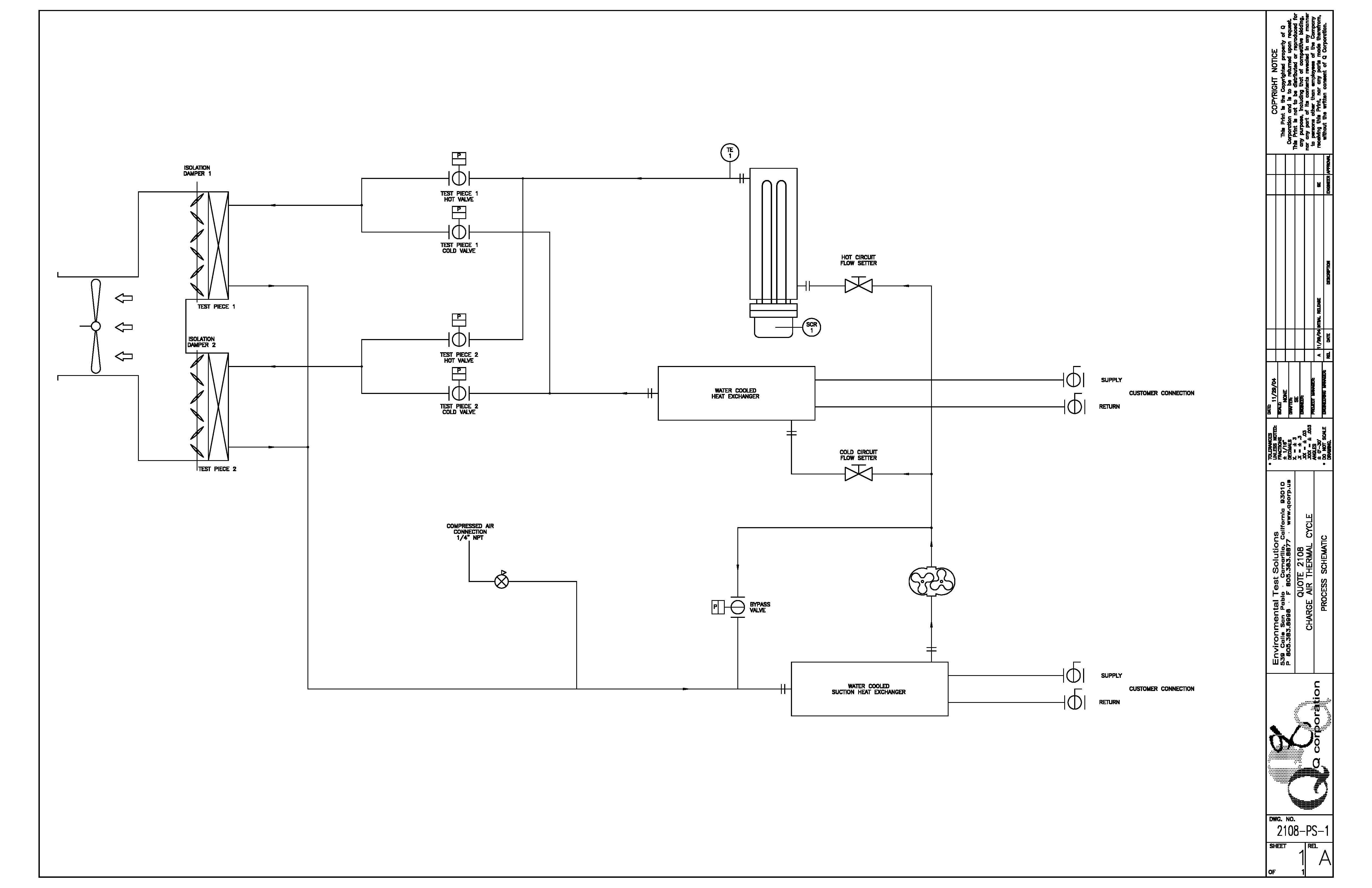

- Q’s standard system will test two-2 UUTs (unit under test) at a time. By design, one unit will operate in a hot cycle, while the counterpart operates in a simultaneous cool cycle.

- The hot circuit will source air from a Q Corp modular charge air supply system (CASS). Once exiting the UUT, the air is further cooled via water to air heat exchanger before returning back to the inlet side of the CASS.

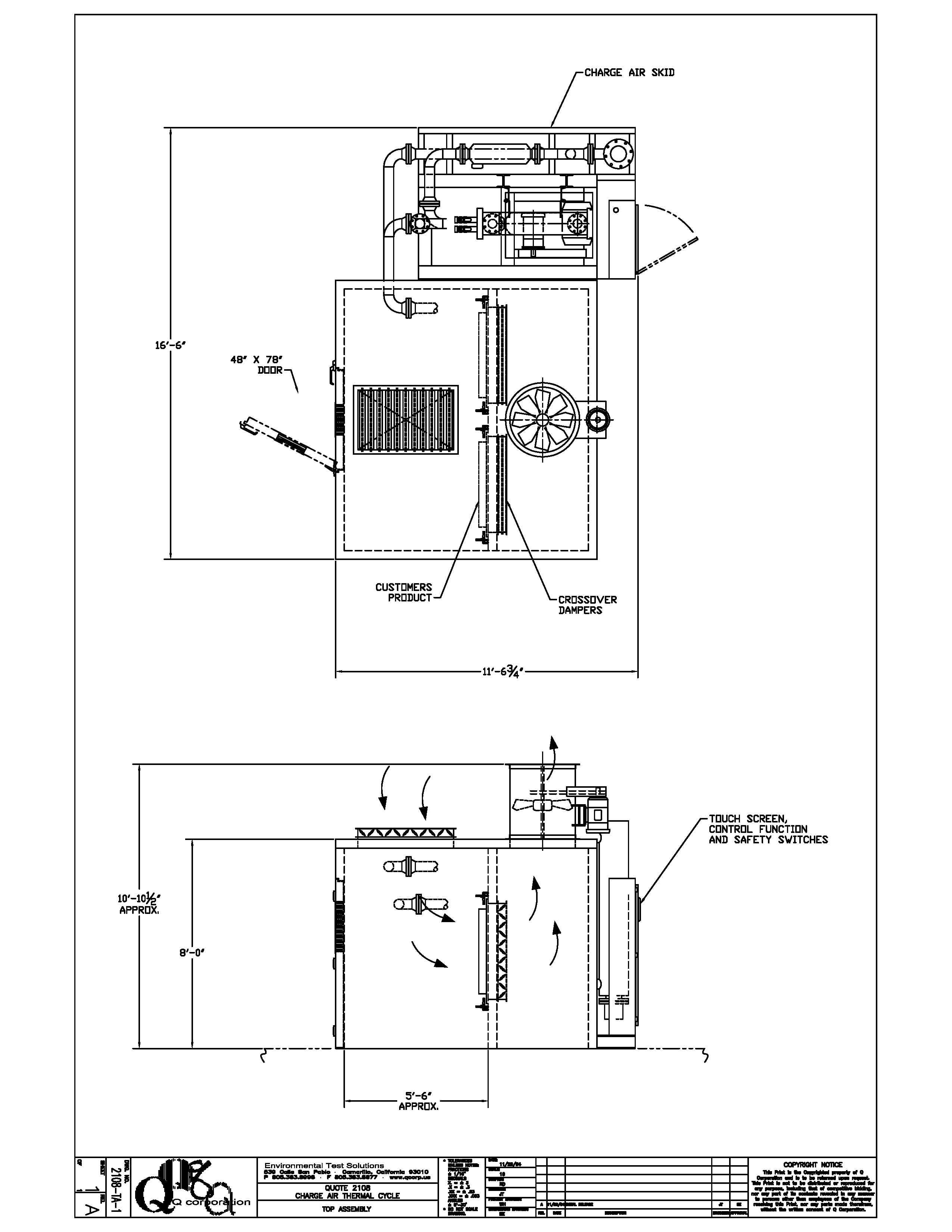

- The surface air (i.e., cool air supply) is routed through an insulated room enclosure. The room is divided into two rooms by a partition in the middle. The units under test (UUT) are mounted on the partition allowing air to pass from one room into the other.

- The open loop cool circuit will source air from the ambient surroundings through a main air supply blower. The air is cooled thru a water to air heat exchanger before entering UUT. Once exiting the UUT, the air is discharged back into the open room environment or ducted to an external location/outside.

Specs

Testing Capacity: 2 parts at a time (standard offering)

Cycle Rate: 30 cycles per hour, typical

Hot Temperature Range: 350° to 700°F+

Cool Temperature Range: Water supply temperature + 12°F to 130°F

Temperature Stability: +/- 10°F

Charge Air Airflow: 10 to 150 lb./min per Unit

Charge Air Supply

Rotary Vane Blower

Variable Speed Drive

Maximum Pressure Drop 6 psi

Temperature Range: Ambient

Control Interface

5,000 to 10,000 cfm

airflow based on cooling requirements

Surface Air Supply

Vane Axial Blower

Variable Speed Drive

Maximum Pressure Drop: 4” Water Column

Digital Control and Alarming

Allen-Bradley Micrologix PLC

PIDs internal to AB 1500

Controllers: Internal to PLC

Digital Outputs: System Alarm, (120V AC)

Communications: RS-232