Today’s tough testing standards demand performance and reliability regardless of the weather conditions. Standard cold start procedures are now being succeeded with more extreme temperature cycling requirements.

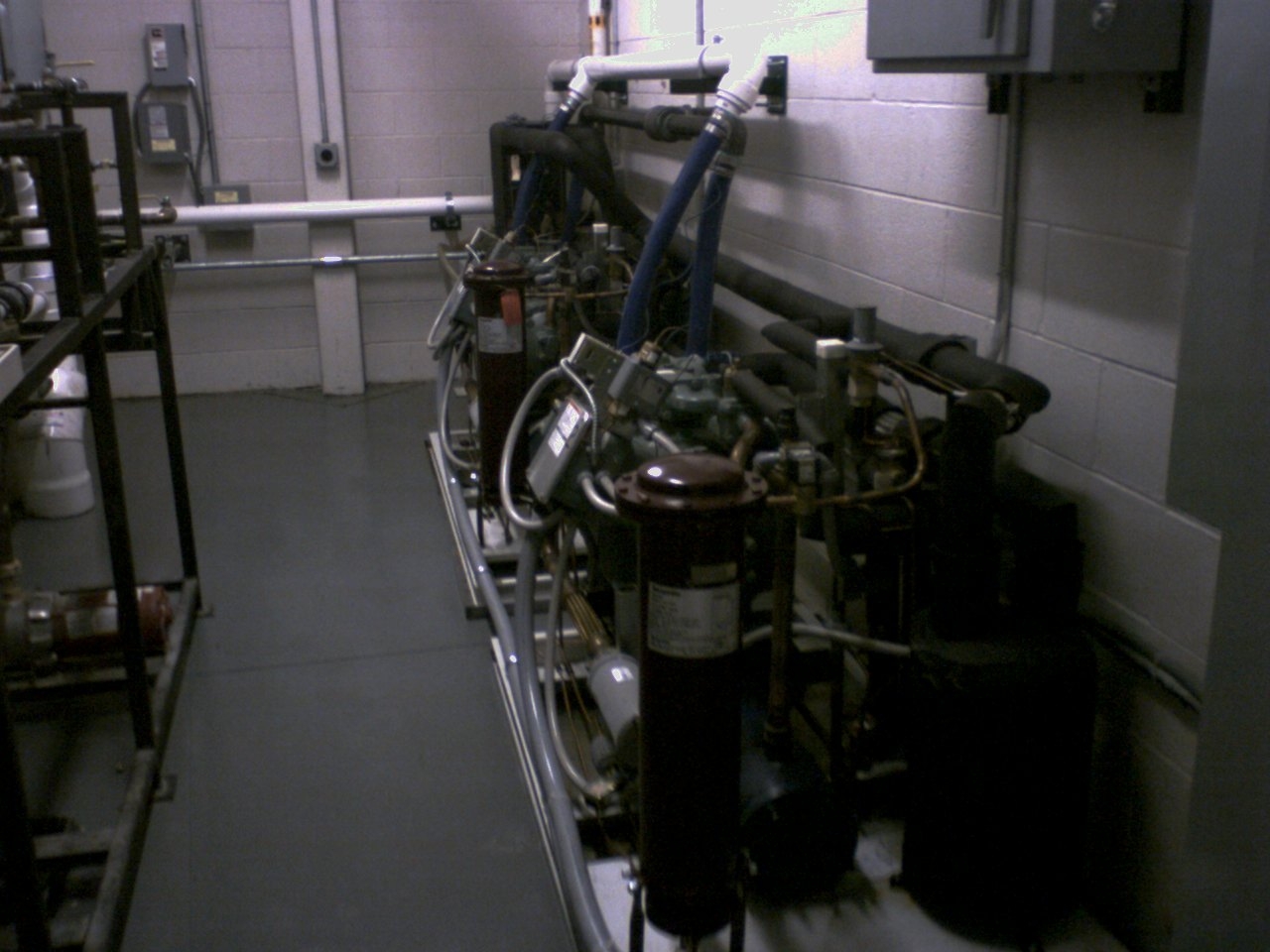

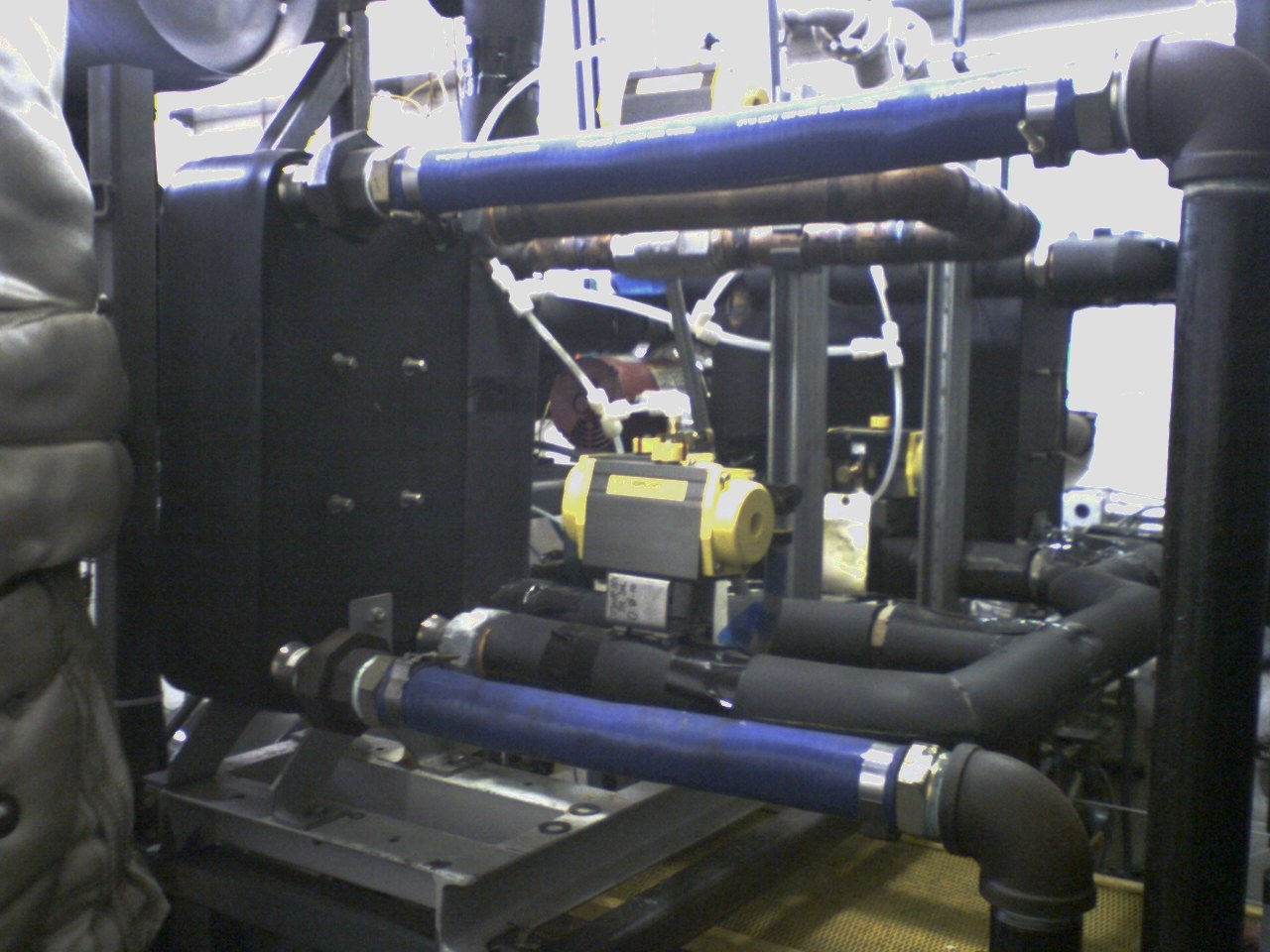

Repetitive and extreme temperature cycling conditions that engine and heat exchanger systems will experience throughout their life cycle has become the standard. Q Corporation manufactures glycol, water and oil supply systems capable of providing accurate flow capacities with precision temperature control.

Although Q Corporation has several standard packaged offerings, we specialize in custom designed systems, including “refrigerant to coolant” and “brine to coolant” systems. Flow capacities ranging from 10 to 150 gpm+, Temperature control from –40 F to 250 F