Automotive Airflow Meter

Features

- Multiple nozzle arrays to achieve high turn down ratios, manually or automatically actuated.

- Variable speed blower to control based on airflow or pressure

- Rugged CRS or clear polycarbonate (also used for bullet proof glass, safety goggles applications) for extreme ruggedness and complete visibility of the nozzles

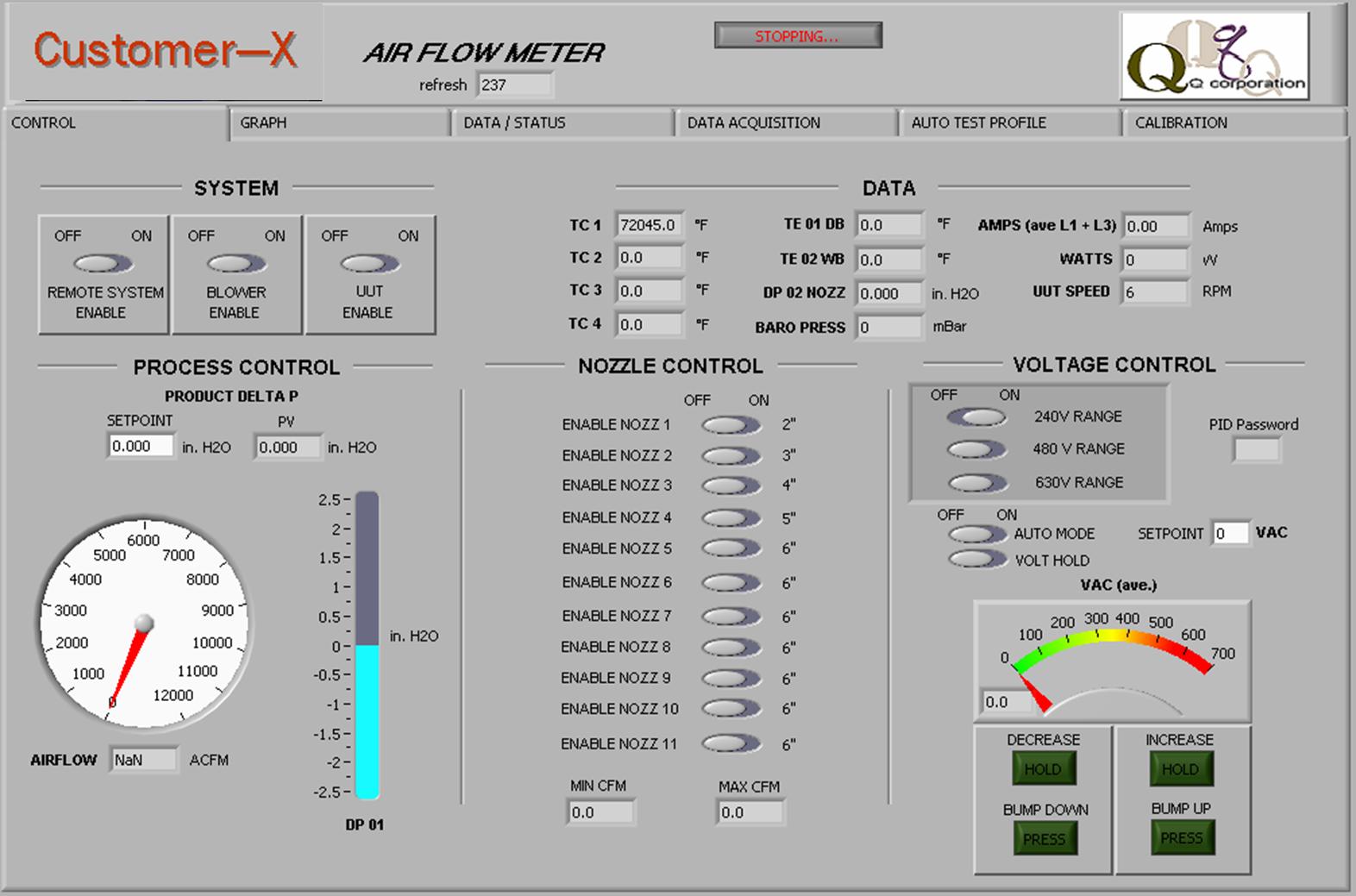

- Data collection and computation through PLC based touch screen, also available through LabVIEW® automation software packages.

- Used as a stand alone system or integrated with other Q Corporation supporting modules, including coolant or refrigerant supply systems.

Specs

Airflow: Up to 10,000 CFM+

Airflow Ranges: Turndown 20:1

Product Pressure Differential: 2” to 10” H2O

Variable Measurement Includes: Inlet Temperature / Inlet Humidity

Pressure Sensor(s): Nozzle Differential Pressure, Barometric Pressure, Product Inlet Pressure

Humidity Sensor(s): RH Capacitive Element

Material: Painted Cold Rolled Steel continuously welded, Lexan, clear polycarbonate

Sizing: Dimensions according to ASHRAE 41.7, AMCA 210

Control: Manual of Fully Automatic

Control Interface: Manual Adjustment, Touch Screen or LabVIEW® software with PC interface